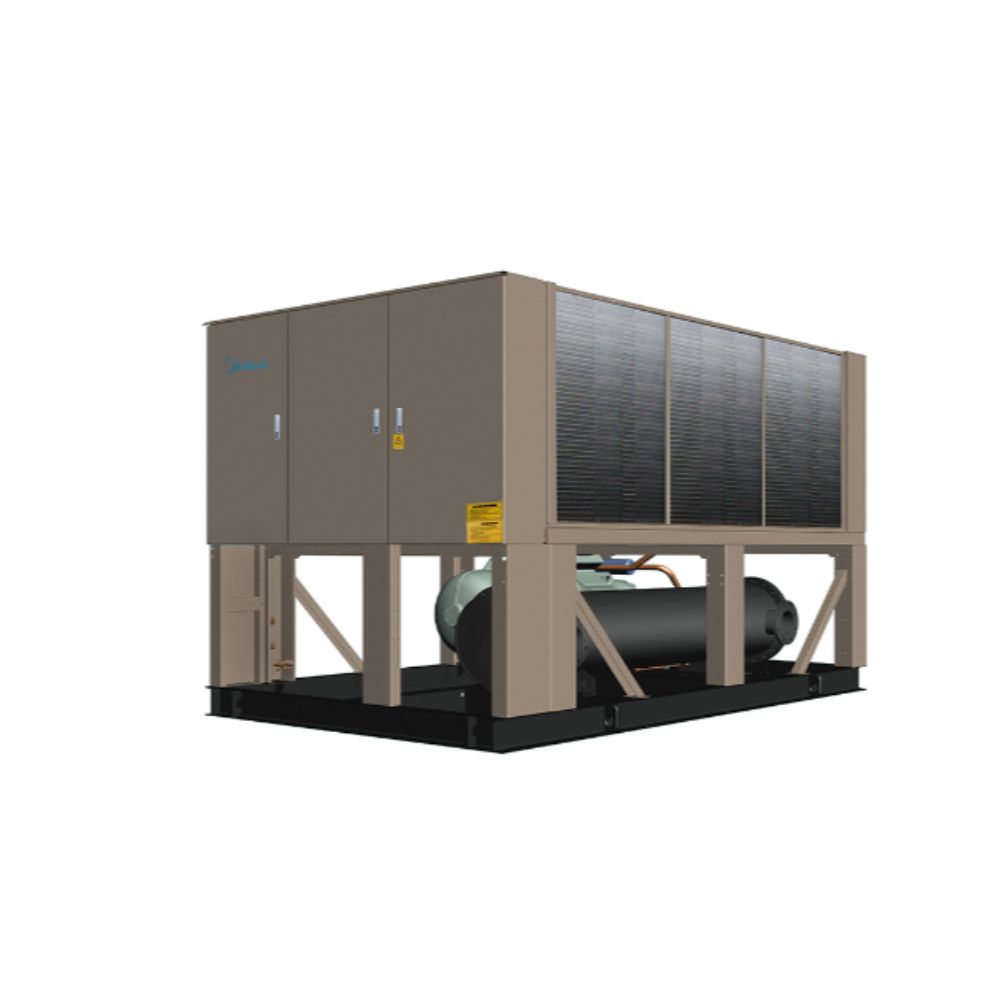

Description

NES air-cooled screw chillers are designed to meet current and future requirements in terms of reliability, energy efficiency and intelligent control. We use the best technologies available today: Twin-rotor screw compressors with a variable capacity valve are ideally matched to coolers and condensers optimally configured for superior heat transfer and unit efficiency. It is ideal for schools, hospitals, shopping malls, office buildings as well as factories and manufacturing plants.

Lowest total cost of ownership

Reliability, low risk of uncomfortable downtime. The best parts, Bitzer Comp. &Danfoss EXV, Shneider electric. World-class testing facilities ensure the performance and reliability. Each unit was extensively tested to verify its operational reliability and to ensure a smooth startup. Serviceability, low maintenance costs.

Silent operation

Larger dimension impellers reduced speed causing less noise. The lower ambient temperature, the lower fan air flow, then reduce noise. Intelligent control logic balance the performance and working fan numbers to control the noise and power consumption. Super low noise model is optional.

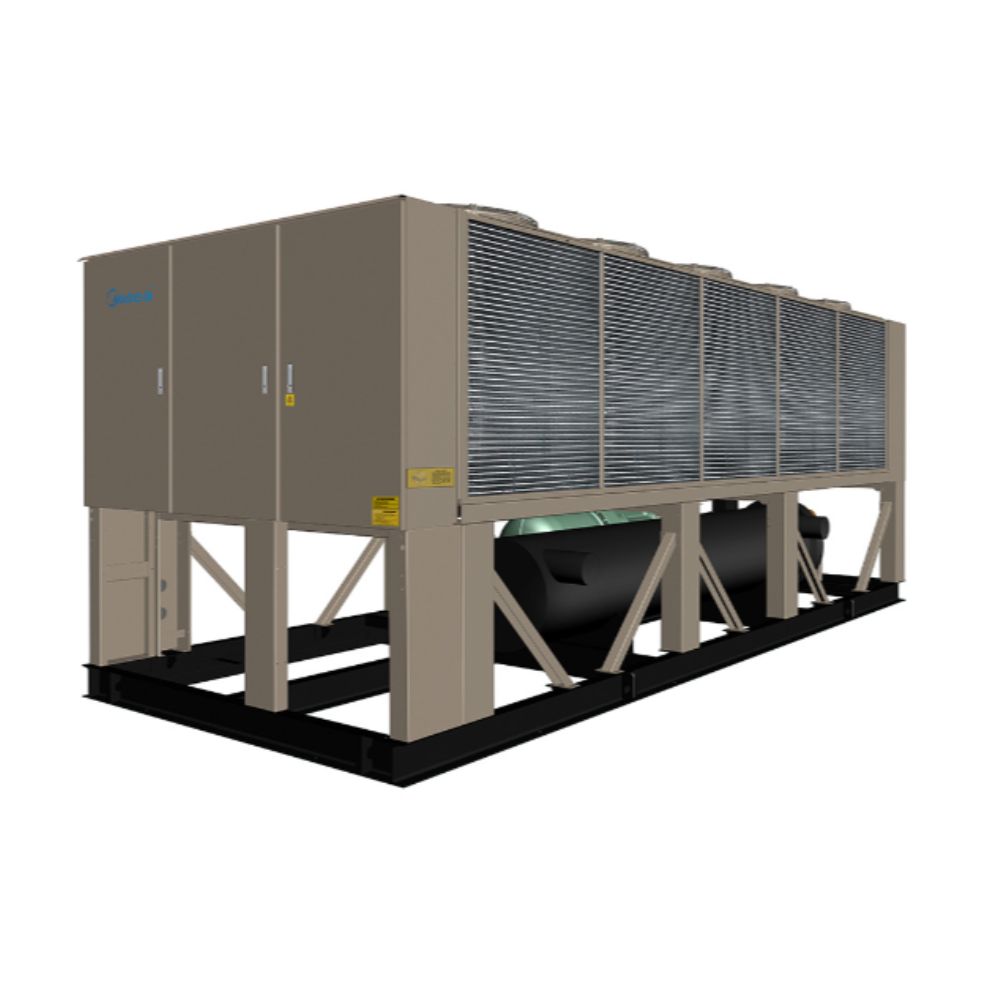

Design flexibility

Six basic capacity modules, wide array of module combination. Standard module for flexible stock and fast delivery. Field-coupled to meet large project tonnage requirements. Low initial investment and maintenance cost.

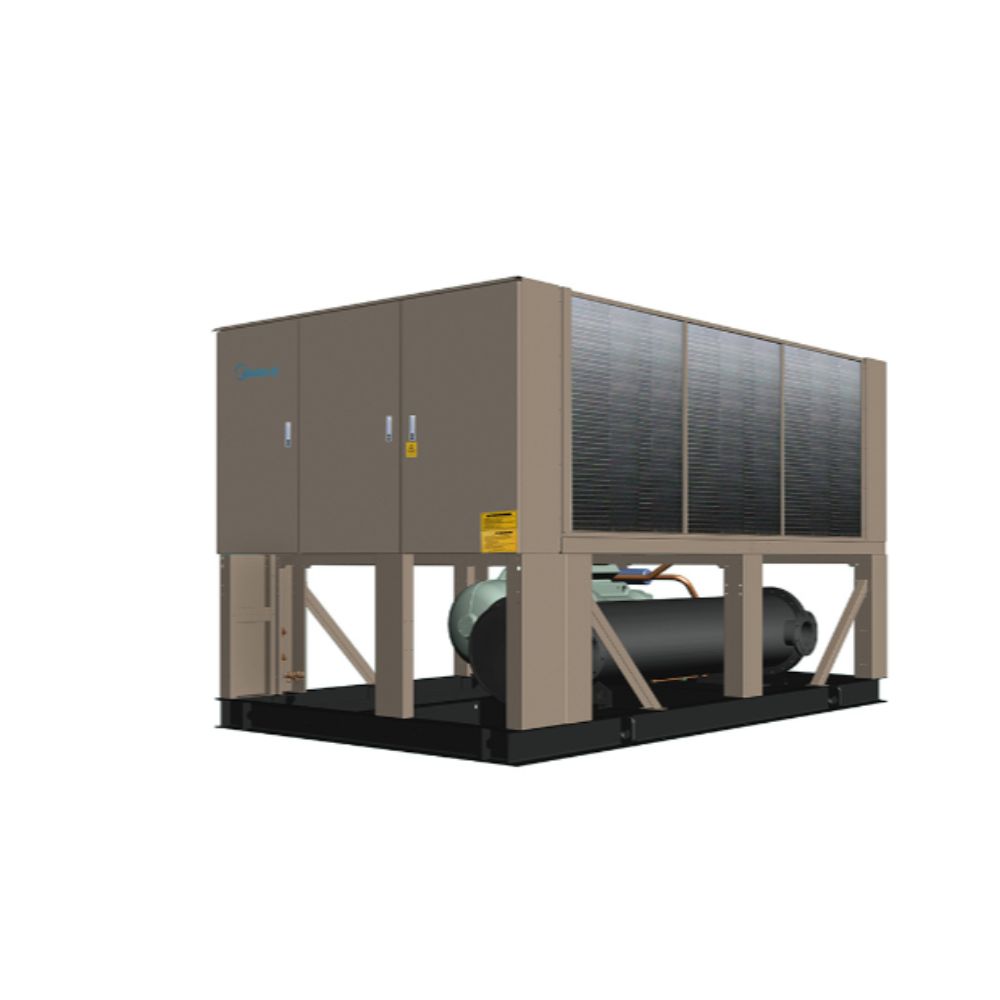

Easy and fast installation

Compact size and module design save the transportation, lifting and installation cost. The unit can be placed in service after being connected with power supply and water supply during field installation.

Reviews

There are no reviews yet.